The options in the environment and winemaking that are appropriate for sparkling wine differ in some respects from those for still wine.

This section summarizes the standard options for making sparkling wine.

もくじ

1. Making Sparkling Wine

1. Viticulture

The qualities of the grapes required for a high quality sparkling wine are as follows.

- Possesses high acidity (medium (+) to high)

- Low alcohol potential (9 – 11%)

→ 1 – 2% alcohol is added during the secondary fermentation that takes place in many sparkling wines - The intensity of the fruitiness is reduced.

Therefore, cooler climates, where the grapes ripen slowly while retaining their acidity, are ideal for sparkling wine. Areas not normally planted with still wine grapes may also be planted with sparkling grapes.

There are three or a combination of factors that contribute to a cool climate in an area.

- High latitude areas (England, Tasmania, etc.)

- Areas near the coast (e.g. Sonoma Coast)

- High elevation (e.g. Torento)

In addition, the qualities required for sparkling wine (high acidity, low alcohol potential, and delicate flavors) can be obtained through high yields. The ability to harvest grapes earlier than with still wines and to maximize production are advantages for producers.

| Options | Advantages | Disadvantages |

|---|---|---|

| Early harvest | ・Reducing risk of mildew | ・Risk of unripe flavors |

| Hand harvest | ・Eliminates diseased grapes during selection at harvest ・Minimizes crushing of the berries | ・Needs to long harvest time (may not be harvested at desired ripeness) ・High labor costs |

In addition, growers need to pay attention to obtaining clean and healthy fruits. The reasons for this are as follows.

- The foreign flavors produced by diseased fruit are accentuated by foaming.

- The enzyme laccase, released by Botrytis-infected grapes, can cause severe oxidation.

2. Grape Variety

The most commonly used varieties for making premium sparkling wine are Chardonnay and Pinot Noir.

| Factor | Chardonnay | Pinot Noir |

|---|---|---|

| Flavor | ・Aromas of apple and citrus ・Biscuits from lees aging | |

| Acidity | Medium (+) 〜 High | High |

| Alcohol | Low | |

| Advantages | ・Cooler climate allows flavors to ripen faster ・High yields in good years | ・Early ripening makes it suitable for cooler climates ・Gives body to the blend |

| Disadvantages | ・Early budding (susceptible to spring frosts) ・Susceptible to coulure and millerandage ・Rot from botrytis before harvest | ・Early budding ・Susceptible to diseases due to thin skin (mildew, powdery mildew, Botrytis rot, leafroll) |

Many other grape varieties are used to make sparkling wine around the world, and some of the factors that influence the style of wine include.

- Ability to retain high acidity

- Intensity of aromas (neutral, fruit-suppressed varieties are preferred, but some regions use aromatic varieties)

- Compatibility of the base wine with the autolysis

3. Winemaking

1. Pressing

Whole bunch pressing is often used for premium wines, and is often regulated by PDO.

- The advantage is that it is the gentlest pressing method (less phenols are extracted and delicate juice can be extracted).

- The disadvantage is that the number of bunches that can be fed into the press at one time is small, so the process takes time.

Other than whole bunch presses, there are pneumatic and basket presses that can be used for gentle pressing as well.

There are two types of juice: free-run juice and pressed juice. Pressed juice has higher phenols and pH solids, and pH levels and higher solids content. It is used for early drinking wines due to its shorter aging time.

The juice is clarified before primary fermentation, and any excess tannin or color is adjusted at this stage.

2. Primary Fermentation

①Primary Fermentation

Since primary fermentation needs to be done reliably and soundly, it is generally carried out in the following manner.

- Performed at 14 to 20°C

- To preserve the flavor of the fruit.

- An environment that is too cold for the yeast and a low pH is stressful.

- Fermentation takes place in stainless steel tanks

- Stainless steel tanks are capable of fermenting in large quantities while maintaining temperature control.

- Easy to clean tanks before and after fermentation

- Use cultured yeast that can handle both primary and secondary fermentation (generally, “Prise de mousse (EC1118)” is used).

- Yeast requirements for Primary fermentation

- Yeast that can reliably ferment even under conditions of high acidity and low pH

- A fully alcoholic wine is required for the secondary fermentation.

- Neutral yeasts are preferred, as pronounced primary aromas are not desirable.

- Yeast that can reliably ferment even under conditions of high acidity and low pH

- Yeast requirements for Secondary fermentation

- Able to initiate fermentation in an environment with high alcohol content and low pH.

- Able to continue fermentation at low temperatures, high pressure and low nutrient levels.

- Yeast requirements for Primary fermentation

②Malolactic Fermentation

The choice of whether or not to perform malolactic fermentation depends on the region and the style the producer is aiming for. The purposes of malolactic fermentation are as follows

- Reduce the acidity of the wine

- Enhance the texture (but without the buttery notes found in white wines. This is due to the fact that “diacetyl” is metabolized by the yeast during the secondary fermentation.)

- Avoid the risk of unintentional malolactic fermentation during secondary fermentation (filtration is an option to make the wine sterile).

③Aging of Base Wine

Some winemakers age their base wines in oak barrels. However, since oak flavors (vanilla, toast, spice, etc.) are amplified by secondary fermentation, only a small percentage of new oak is used.

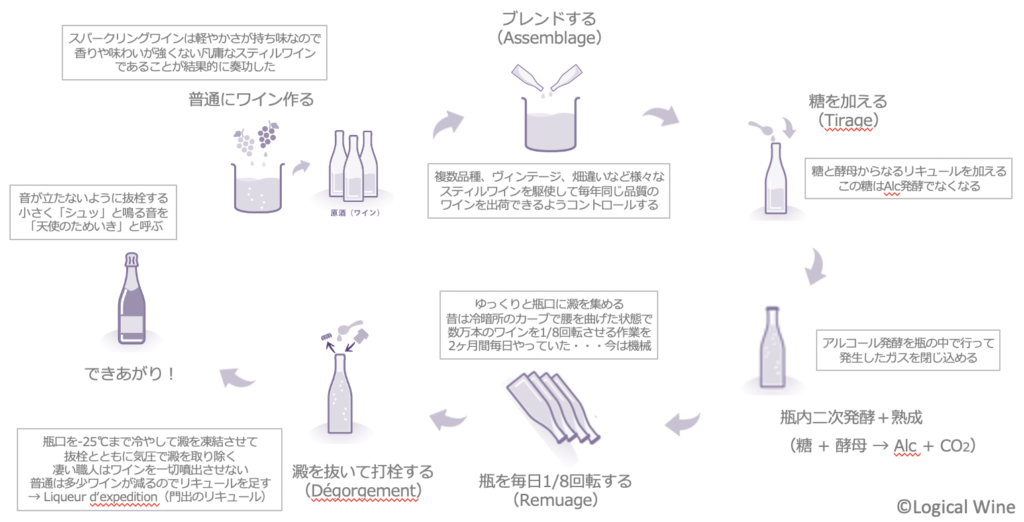

3. Blending(Assemblage)

In the production of sparkling wine, four blends may be made.

- Different Vineyards

- Grape Variety

- Different Vintages

- Different Vinification Methods

The purpose of blending is as floows

| Balancing | Adding varietal character or vineyard differences (e.g. PN or warm vineyard body) |

| Maintaining Consistency | Blending vintages to maintain consistency of product from year to year |

| Objective Style | To achieve each producer’s desired style, such as early drinking style or a style that can be aged for a long time |

| Rosé Wine Production | Blending red and white wines to produce rosé wines (some PDOs do not allow blending) |

| Complementary Complexity | Blending of varietals, vineyards, vintages and some barrel-aged wines to provide complexity in aroma and taste |

| Defect Minimization | If some of the wine is defective, blending it with a large quantity of healthy wine will reduce the exposure of the defect. |

| Compensating for Production Volume | Blending can compensate for low vineyard area in a particular area. |

| Price Adjustment | Price adjustments can be made by blending expensive grapes with less expensive grapes (e.g. Meunier blends in Champagne). |

Wines blended for this purpose are clarified and then subjected to secondary fermentation.

4. Secondary Fermentation

The secondary fermentation process is as follows.

| # | Method | Overview |

|---|---|---|

| A | Traditional | A Traditional method of secondary fermentation in the same bottle as the wine to be sold. |

| B | Transfer | A method that maintains the aroma of autolysis while reducing the cost of Traditional method. |

| C | Ancestral | A primitive method, revived by small producers around the world as Pet Nat, short for Pétillant naturel. |

| D | Tank | Also known as the Sharmat method, used to produce inexpensive sparkling wine. |

| E | Carbonation | The simplest method of producing low-pressure, inexpensive sparkling wine. |

A. Traditional Method

Traditional method of secondary fermentation in the same bottle as the wine to be sold.

A-4. Secondary Fermentation

For the secondary fermentation, a “liqueur de tirage” is added to the base wine.

The “liqueur de tirage” is a mixture of wine, must, sugar, cultured yeast, yeast nutrients, and clarifying agents such as bentonite and alginate.

24 g sucrose per liter

↓

1.5% alcohol and CO2 (equivalent to 6 atmospheres)

Secondary fermentation takes place under the following conditions

- Fermentation begins with wine at 9.5-11% alcohol, temperature around 16°C, pH below 3

- Bottles are stored in “sur latte” (bottles lying horizontally at a temperature of 10-12°C)

- Fermentation lasts 4 to 6 weeks

A-5. Aging on Lees

After fermentation is complete, the wine is left to mature with the yeast intact. The maturation period is regulated by the PDO, and after 15 months, the effects of autolysis become apparent.

The advantages of lees aging are as follows

- Autolysis, the enzymatic degradation of dead yeast cells, produces compounds that give biscuit-like complexity.

- Autolysis lasts 4 to 5 years, and in some cases up to 10 years.

- Yeast cells have antioxidant properties, so there is a benefit to leaving them on the lees after autolysis is complete (although the longer this period, the faster the wine will change after discharge. For this reason, it is advisable to drink immediately after release).

A-6. Bottling(Riddling → Degorgement → liqueur d’expédition)

After maturation, the wine is riddled to remove the lees, followed by “Dégorgement” and “liqueur d’expédition”.

①Riddling

After the wine has finished maturing, it is riddled in order to collect the lees at the mouth of the bottle. The lees are collected by turning the bottle upside down and shaking it while rotating it.

- Manual (pupitres):8 weeks

- Automatic (gyropalettes):3 to 4 days

If the wine is not to be racked immediately, it is stored in an upside-down container called a “sur pointe”.

②Dégorgement

De-racking needs to be done with minimal loss of wine and pressure, and is automated today.

- Cool the bottle to about 7°C (the solubility of CO2 is increased, thus reducing wine effervescence)

- Immerse the neck in freezing brine (this freezes the yeast sediment, facilitates extraction and prevents sediment from falling)

- Set the bottle upright.

- Remove the crown cap and eject the yeast and plug by pressure inside the bottle

③liqueur d’expédition

Before bottling, a “liqueur d’expédition” is added. “liqueur d’expédition” is a mixture of wine and sugar (Dosage) or RCGM (Rectified Concentrated Grape Must). It is a mixture of wine and sugar (dosage) or RCGM (Rectified Concentrated Grape Must) and has the following advantages

- Balance with acidity (some is needed, especially in young wines, as acidity rounds out with long aging)

- Maillard reaction with compounds produced during yeast autolysis, resulting in aromas of roasted and toasted vanilla.

B. Transfer Method

This method was originally developed to avoid the cost of manual bottling, but the benefits have diminished as the bottling and de-racking process has become more automated.

The transfer method is also allowed in Champagne for bottles smaller than 375 ml or larger than 3,000 ml, where bottle transfer is difficult.

The transfer method is as follows

- The second fermentation takes place in the bottle, just as in the traditional method.

- There is no need to add fining agents to the “liqueur de tirage” because there is no bottle movement.

- The aged wine is cooled to 0°C and discharged into a pressurized receiver tank.

- Dosage and SO2 are added, then the wine is filtered and bottled.

C. Ancestral Method

A method for producing sparkling in primary fermentation by placing partially fermented must in a bottle.

- By measuring the sugar content of the partially fermented must, the final pressure level can be estimated.

- Dead yeast sediment accumulates in the bottle, but it is the winery’s decision whether or not to remove it.

- There is no involvement after bottling, so the final wine quality will vary.

- Dosage is generally not done, but after a few months, the yeast cannot survive due to lack of nutrients, so sugar generally remain in the final product.

D. Tank Method

Since the tank method does not require long periods of lees aging with dynamic bottling, degorgement, and secondary fermentation, it is possible to mass produce inexpensive wines at low cost.

- Aromatic varieties are also used to emphasize the primary aromas.

- Primary fermentation takes place at 16-18°C (to preserve fresh floral and fruity aromas)

- Secondary fermentation takes place in pressurized tanks with sugar and yeast in as little as one month (sometimes the wine is left on the lees for a longer period of time, but pressurized tanks are expensive and therefore less economical).

- Once the wine has reached the desired pressure and sugar content, it is cooled to 2-4°C to stop fermentation.

Asti Method

A variation of the tank method, in which sparkling wine is produced in a single fermentation.

- Sugar is provided by the original must, not the tirage.

- In the early stages of fermentation, CO2 is vented through a valve.

- The sugar and pressure levels are measured and the bubble is closed during fermentation, after which the CO2 is retained.

- When the desired sugar and pressure levels are reached, the wine is rapidly chilled to stop fermentation.

- The wine is filtered under pressure to remove the yeast and bottled.

E. Carbonation

A method of injecting carbon dioxide while the wine is under pressure.

The quality of the base wine is important because it can retain the aromas and flavors of the base wine, but it can also highlight flaws.

2. Sweetness Description, Foram Condition, etc.

1. Sweetness Description

The EU has established rules for residual sugar content and labeling, and many regions outside the EU also use labeling in accordance with these rules.

| Residual Sugar | Major Indications | Indications by Region |

|---|---|---|

| 0〜3g | Brut Nature | Bruto Natural / Naturherb Zeto Dosage |

| 0〜6g | Extra Brut | Extra Bruto / Extra Herb |

| 0〜12g | Brut | Bruto / Herb |

| 12〜17g | Extra-Sec | Extra-Dry Extra Trocken |

| 17〜32g | Sec | Secco / Dry / Trocken |

| 32〜50g | Demi-Sec | Semi-Seco / Medium-Dry Abboccato / Halbtrocken |

| 50+ g | Doux | Dolce / Sweet / Mild |

2. State of the Form

Since there are many variables involved in the size, condition and formation of bubbles, WSET does not mention them extensively.

- Sugar content of the grapes (potential alcohol content)

- The ability of CO2 to dissolve into the wine (dependent on many factors including grape variety, health, and sugar content)

- Duration of lees aging (the longer the aging period, the more CO2 is lost but the longer the bubbles last)

- Degorgement process (degree of CO2 loss)

- Size and shape of the glass, cleaning conditions, temperature of the wine, etc.

3. How to Seal the bottle

Cork is generally used to seal sparkling wine.

- The diameter of the cork is 31mm, compared to the inner diameter of the bottle neck of 18-21mm. This causes the cork to compress and take on a “mushroom” shape.

- Generally, Agglomerate Cork is used, which is two pieces of natural cork glued together.

3. Major Regions of Sparkling Wine

The sparkling wine regions handled by WSET are listed below, and the characteristics and regulations of each region are summarized in the links.

> Summary of Major Regions in Sparkling Wine

- France

- Champagne

- Crémant d’Alsace

- Crémant de Bourgogne

- Crémant de Loire

- Saumur Mousseux

- Vouvray Mousseux

- Spain(Cava)

- Italy

- Prosecco

- Asti

- Lambrusco

- Franciacorta

- Trento

- Germany

- Sekt

- Perlwein

- England & Wales

- USA

- Chile

- Argentina

- South Africa

- Australia

- New Zealand

The information contained herein is based on the content of the WSET D4 textbook, but the accuracy of the content is not guaranteed.